OSHA Decibel Limit: Understanding the OSHA Noise Standard

Knowing the osha decibel limit is crucial for ensuring workplace safety and preventing noise-induced hearing loss among employees. The Occupational Safety and Health Administration (OSHA) has established strict noise standards that define the acceptable level of sound exposure over a given period. In this article, we’ll break down what the OSHA noise standard means, how decibel levels are measured, and the steps employers can take to maintain compliance while promoting a healthier, quieter work environment.

Overview of OSHA Noise Standards

OSHA has rules to limit workplace noise and protect workers’ hearing. Long-term exposure to loud sounds can damage the tiny hair cells in your inner ear, which are crucial for hearing. Once these cells are damaged, the hearing loss is permanent. Continuous loud noise can also cause ringing or buzzing in the ears, making it difficult to sleep, focus, or carry out daily tasks.

Legal Standard (29 CFR 1910.95):

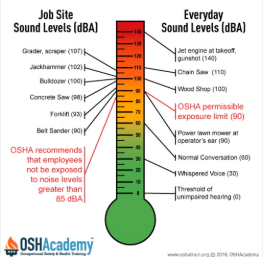

- Permissible Exposure Limit (PEL): Noise should not exceed 90 decibels (dBA) averaged over an 8-hour workday. Exposure above this level increases the risk of hearing damage.

- Action Level: When noise reaches 85 dBA averaged over 8 hours, employers must implement a hearing conservation program, which includes:

- Monitoring workplace noise levels.

- Providing hearing protection like earplugs or earmuffs.

- Conducting audiometric (hearing) testing for employees.

- Offering training on noise risks and proper use of protection.

- Keeping records of noise exposure and protection measures.

Who Is Most Affected:

Jobs and industries where noise levels are consistently high include:

- Construction: Power tools, jackhammers, heavy machinery.

- Manufacturing: Presses, motors, conveyors, and factory equipment.

- Aviation: Airports, aircraft engines, maintenance operations.

- Transportation: Trains, trucks, and shipping operations.

Workers in these environments are at higher risk of hearing loss and require ongoing monitoring and protection.

Impact of Enforcing OSHA Noise Standards:

By regulating noise and requiring hearing conservation programs, OSHA:

- Prevents hearing loss, one of the most common occupational illnesses.

- Protects long-term worker health, allowing employees to maintain their hearing throughout their careers.

- Improves workplace safety, as workers with good hearing can better respond to alarms and warnings.

Measuring Decibel Levels

Measuring workplace noise is essential to protect employees from hearing damage and ensure compliance with OSHA standards.

Key Methods and Tools:

- Sound Level Meters: Hand-held devices used to quickly measure how loud the noise is at a specific spot in the workplace.

- Integrating Sound Meters: Devices that track noise over a period of time to calculate the average sound level, including any changes or fluctuations.

- Dosimeters: Devices that workers wear to measure noise exposure throughout their entire shift and calculate the average exposure over time.

Importance of Accuracy:

- Accurate measurements identify high-risk areas and verify that controls are effective.

- Instruments must be properly calibrated to ensure trustworthy data.

Accurately checking noise levels helps employers protect workers’ hearing, keep the workplace safe, and follow safety rules.

Compliance and Safety Measures

To comply with OSHA noise standards and protect workers, employers must implement several safety measures:

- Noise Monitoring: Regularly measure workplace noise using sound level meters or dosimeters to identify at-risk employees.

- Hearing Conservation Program: Required when noise reaches 85 dBA over 8 hours. Includes:

- Audiometric testing.

- Providing hearing protection.

- Employee training.

- Recordkeeping

- Hearing Protection: Provide workers with earplugs or earmuffs for free. Make sure they fit properly, are used correctly, and are replaced when worn out.

- Engineering and Administrative Controls: Methods used to reduce workers’ noise exposure by making equipment quieter or adding barriers and limiting exposure time through schedules or task rotation.

- Training and Education: Show workers how noise can harm their hearing, how to use ear protection correctly, and why it’s important to report any problems.

- Recordkeeping: Maintain records of noise measurements, hearing tests, training, and equipment calibration to demonstrate compliance.

Following safety rules helps protect workers’ hearing and keeps the workplace safe for everyone.

Benefits of Compliance

Following OSHA noise standards and hearing conservation programs provides important benefits for both workers and employers:

- Protects Hearing Health: Proper noise protection prevents permanent hearing loss and tinnitus, helping employees maintain their hearing over time.

- Enhances Workplace Safety: Good hearing is essential for noticing potential dangers in the workplace. Clear hearing helps workers notice dangers and react quickly to prevent accidents. This reduces the chances of accidents, injuries, and mistakes, making the work environment safer for everyone.

- Reduces Costs: Protecting workers’ hearing can save the company money. Preventing hearing damage reduces medical costs, compensation claims, and lost workdays. This reduces expenses and keeps productivity high, benefiting both the employer and the workforce.

- Ensures Legal Compliance: Following OSHA noise rules keeps a company within the law and helps avoid fines, penalties, or lawsuits from exposing workers to harmful noise.

- Improves Employee Morale: When employers take steps to protect workers’ hearing, it shows they care about their health and safety. This builds trust, makes employees feel valued, increases loyalty, and boosts overall job satisfaction.

- Promotes Long-Term Productivity: Protecting workers’ hearing helps them stay healthy and work effectively. Good hearing allows employees to communicate clearly, respond quickly in noisy environments, and maintain high performance, which supports long-term productivity.

Compliance with OSHA noise standards protects workers’ hearing, improves safety, reduces costs, ensures legal compliance, boosts morale, and supports long-term productivity.

Control Strategies and Measurement Tools

Hierarchy of Controls

OSHA recommends using long-term solutions first to reduce noise exposure:

- Engineering Controls: Methods that reduce or eliminate noise at its source, such as using quieter machines, enclosing noisy equipment, or adding sound barriers.

- Administrative Controls: Reduce workers’ exposure to noise by changing work schedules, rotating tasks, or moving employees to quieter areas.

- Personal Protective Equipment (PPE): Devices like earplugs or earmuffs that protect workers’ hearing, used after engineering and administrative controls have been applied.

Measuring Noise

Accurate measurements are key to protecting hearing:

- Sound Level Meters: Hand-held devices for quick spot checks.

- Integrating Meters: Measure average noise over time.

- Dosimeters: Worn by workers to track full-shift exposure and calculate time-weighted averages.

- Other Tools: Mobile apps and frequency analyzers can help with initial checks, but professional, calibrated instruments are needed for reliable results.

Why Accuracy Matters:

Correct measurements ensure workers are protected and that employers meet regulations. Instruments must be calibrated regularly to give trustworthy data.

Going Beyond Compliance:

- OSHA allows 8 hours at 90 dBA (5-dB exchange rate).

- NIOSH recommends stricter limits: 85 dBA, with exposure time halved for every 3 dB increase.

- Following NIOSH guidelines provides extra safety and encourages early noise control at the source.

To protect workers, first reduce noise with engineering and administrative methods, measure noise accurately, use proper hearing protection, and follow stricter safety standards when possible.

Conclusion: OSHA Decibel Limits and Hearing Protection

Understanding and following OSHA noise standards is essential for protecting workers from hearing loss and creating a safer workplace. OSHA sets the Permissible Exposure Limit (PEL) at 90 dBA over an 8-hour workday and requires a hearing conservation program when noise reaches 85 dBA. Compliance involves monitoring noise, using engineering and administrative controls, providing proper hearing protection, training employees, and keeping accurate records.

Accurate measurement of noise using sound level meters, integrating meters, and dosimeters ensures that workers are not overexposed. Following OSHA noise limits and hearing protection programs prevents hearing loss, ensures safety, legal compliance, and more productive workers.